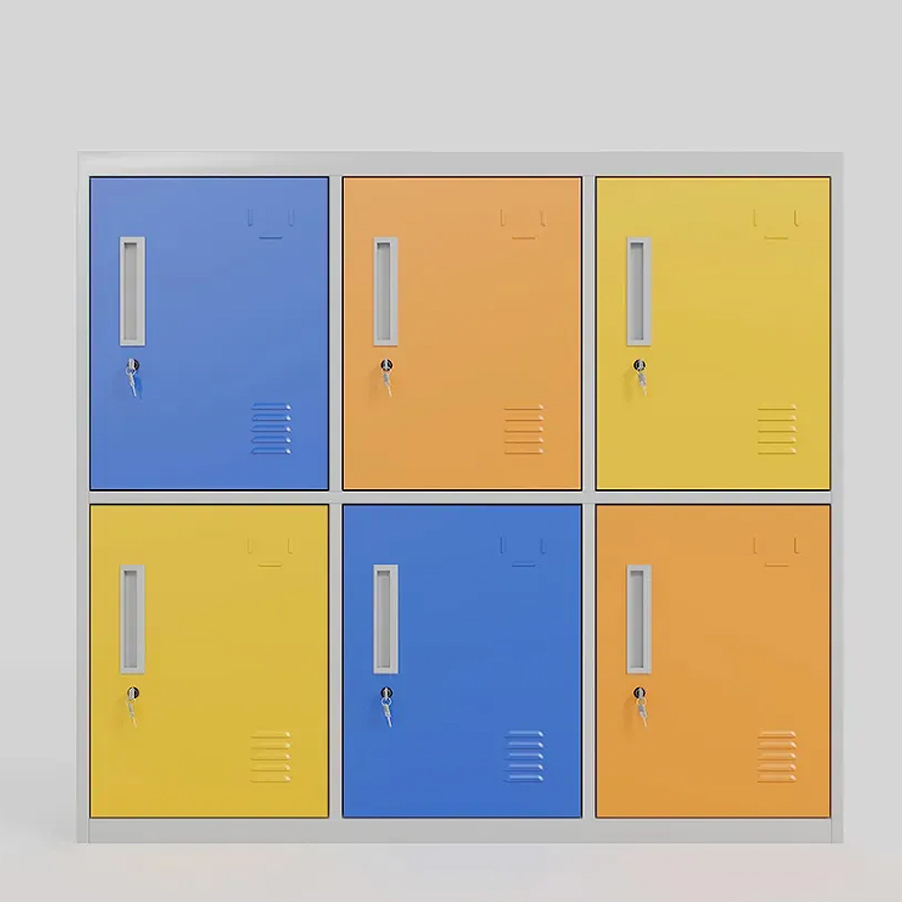

JS Group is a leading Commercial Furniture manufacturer specializing in high-quality furniture solutions, with a strong reputation for delivering durable and functional products. One of the brand's flagship offerings, JSlocker steel cabinets, is renowned for its durability, security, and customizability, meeting the needs of various industries, healthcare, education, and corporate environments.

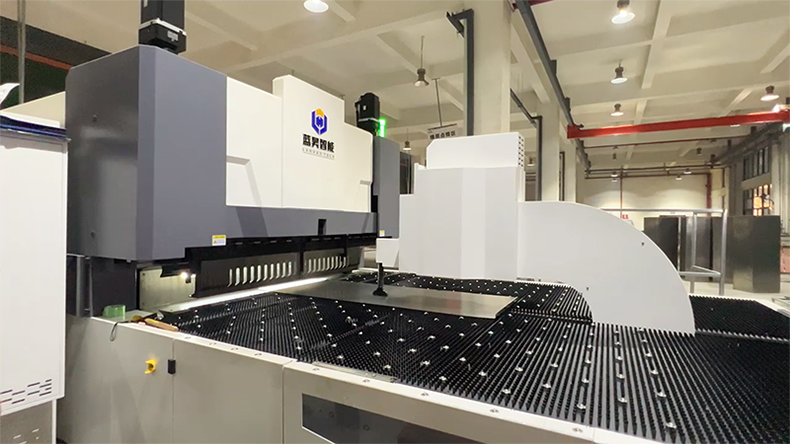

To meet the growing demand for high-performance storage solutions, JS Group has invested significantly in its manufacturing capabilities. The JSlocker steel cabinet production workshop is a key part of this investment, where cutting-edge technology, expert craftsmanship, and efficient processes come together to produce top-tier steel locker for clients worldwide.

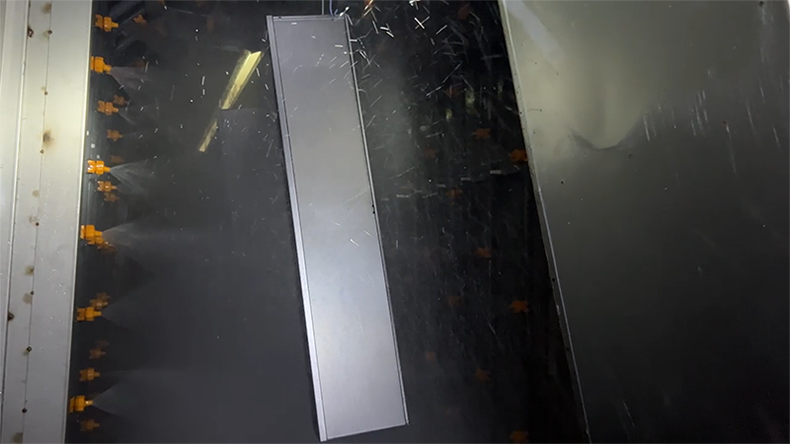

The workshop is divided into several key production areas, each designed to maximize efficiency and output while maintaining the strictest quality control measures:

2. Robotic Welding and Pickling:

4. Assembly and Quality Control:

Furthermore, the JSlocker filing cabinet are designed with flexibility in mind. Clients can customize the size, configuration, and color of the steel cabinets to meet their specific needs, making them an ideal choice for a wide range of applications, from healthcare facilities to corporate offices.

JS Group’s JSlocker metal storage locker production workshop stands as a beacon of innovation and efficiency, producing high-quality storage solutions that meet the diverse needs of industries worldwide. With its cutting-edge technology, expert workforce, and dedication to sustainability, JS Group continues to set new standards for steel furniture manufacturing, delivering durable, secure, and customizable products that enhance organizational efficiency and functionality.